|

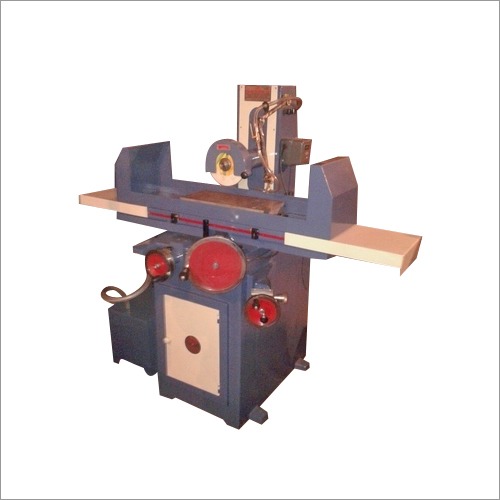

Tool Room Surface Grinder

Price 300000 INR/ Piece

Tool Room Surface Grinder Specification

- Rotation

- Clockwise

- Product Type

- Surface Grinder

- General Use

- Precision Surface Grinding in Tool Room Applications

- Type

- Tool Room Grinder

- Computerized

- No

- Automatic

- No

- Control System

- Manual

- Table Size

- 200 x 450 mm

- Magnetic Chuck Size

- 200 x 450 mm

- Grinding Wheel Size

- 200 x 13 x 31.75 mm

- Grinding Length

- 450 mm

- Floor Space

- 1400 x 1100 mm

- WorkingSpeed

- Variable by Manual Feed

- Feature

- Precision Finish, High Rigidity, Trouble Free Operation

- Color

- Blue/White

Tool Room Surface Grinder Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash on Delivery (COD), Paypal, Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 20 Pieces Per Month

- Delivery Time

- 10 Days

- Sample Available

- No

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- depends on location

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Tool Room Surface Grinder

Tool Room Surface Grinder

Leveraging on our experience, we manufacture, export and supply an extensive range of Tool Room Surface Grinder that works efficiently even on a very low pressure. This Grinding & Milling Machinery is fabricated using superior quality components as per the set industry norms under the guidance of skilled professionals. The entire range of Tool Room Surface Grinder is highly admired for robust construction, improved ergonomics for optimized work flow, flawless performance, high efficiency and low maintenance. The offered range is available in different specifications to meet the exact needs of the clients.

Versatile Tool Room Surface Grinder: Applications and Benefits

The Tool Room Surface Grinder stands as the backbone for precision surface grinding in various tool room applications. Its main advantage is achieving fine, ultra-precise finishes with a high degree of accuracyideal for die, jig, and fixture production. Renowned for consistent results, users employ this machine where reliability and meticulous surface quality are paramount, particularly in manufacturing and maintenance environments. This grinder is specifically used for shaping, finishing, and perfecting metal workpieces, ensuring superior productivity in general tool room tasks.

Domestic Market Reach and Packaging Excellence

Within Indias main domestic markets, these surface grinders are swiftly distributed with meticulous packaging, ensuring product safety throughout freight. Commercial buyers enjoy prompt dispatch, reducing waiting time and additional expenditure. Each unit is securely packed, reflecting an emphasis on both protection and quick delivery. Sampling options are available for verification prior to large orders. With comprehensive after-sales support, customers benefit from a seamless procurement process and timely shipment, making this grinder a preferred choice among manufacturers and traders alike.

FAQs of Tool Room Surface Grinder:

Q: How does the manual microfeed system improve surface grinding precision?

A: The manual microfeed system allows operators to make fine adjustments to the vertical axis, ensuring exceptionally precise material removal for impeccable surface finishes, which is crucial for delicate tool room operations.Q: What types of workpieces can be accommodated on this surface grinder?

A: This grinder is designed to handle workpieces up to 250 mm in height and 200 mm in width, making it ideal for a variety of tool room components like dies, jigs, and fixtures, crafted from cast iron, steel, or similar materials.Q: Where is this Tool Room Surface Grinder typically used?

A: The surface grinder is widely employed in tool rooms, maintenance shops, manufacturing plants, and workshops throughout India and by exporters worldwide who require high-precision ground parts.Q: What are the benefits of having a centralized lubrication and coolant system?

A: A centralized lubrication system simplifies maintenance by ensuring optimal lubricant distribution, reducing wear and tear, while the coolant system enhances grinding performance and prolongs tool life by dissipating heat and removing debris.Q: What is the process for ordering and receiving a sample?

A: Interested buyers can request a sample, which will be securely packaged and quickly dispatched. This enables inspection before placing bulk orders, minimizing expenditure risks and ensuring satisfaction with the products features and quality.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Manual Surface Grinders Category

Surface Grinding Machine

Price 300000 INR / Piece

Minimum Order Quantity : 1 Piece

Computerized : No

Material : Cast Iron

Product Type : Precision Surface Grinding Machine

Manual Surface Grinder Machine

Price 300000 INR

Minimum Order Quantity : 1 Piece

Computerized : No

Material : Cast Iron

Product Type : Manual Surface Grinder Machine

Feature : Other, Durable Structure, Easy Operation, Smooth Finish

Ball type Surface Grinder

Price 300000 INR / Piece

Minimum Order Quantity : 1 Piece

Computerized : No

Material : Cast Iron

Product Type : Surface Grinder

Feature : Other, Heavy Duty Construction

Down Feed Surface Grinder

Price 190000 INR / Piece

Minimum Order Quantity : 1 Piece

Computerized : No

Material : Stainless Steel

Product Type : Down Feed Surface Grinder

Feature : High Performance

|

GURU AMAR DASS MACHINE TOOLS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry