|

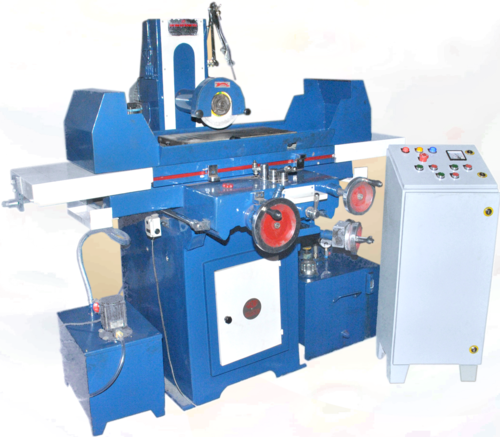

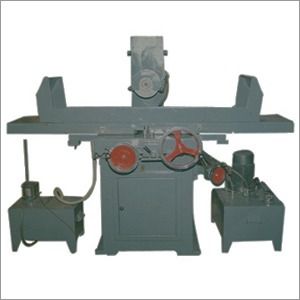

Automatic Surface Grinders

Automatic Surface Grinders Specification

- Efficiency

- High Grinding Efficiency

- Power Source

- Electric

- Application

- Grinding of metal surfaces in workshops, tool rooms, and manufacturing units

- Connectivity Type

- Panel Based Controls

- Mounting Type

- Floor Mounted

- Accessories

- Magnetic Chuck, Coolant Pump, Wheel Balancing Stand, Diamond Dresser

- Sealing Type

- Precision Sealed

- Flow Rate

- up to 20 LPM

- Body Material

- Cast Iron, Mild Steel

- Type

- Automatic Surface Grinder

- Structure

- Box type robust structure

- Force

- Hydraulic/Servo force

Automatic Surface Grinders Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash on Delivery (COD), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 20 Pieces Per Month

- Delivery Time

- 10 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- depends on location

- Main Domestic Market

- All India

About Automatic Surface Grinders

By keeping track with current market developments, we are offering Automatic Surface Grinders that are made from one piece casting bases with sturdy box type construction reinforced with support ribs for high rigidity.i This Grinding & Milling Machinery is fabricated from components at our well-equipped production unit in conformity to the international standards of quality. Owing to optimum functionality, ability to adverse conditions, longer service life and high performance, the offered Automatic Surface Grinders is highly demanded in the market.

i

Versatile Usage and Application Areas

Automatic Surface Grinders are extensively used by manufacturers, workshops, tool rooms, and metal fabrication units for precise grinding of metal surfaces. These machines are also indispensable in die making, mold industries, and maintenance departments. They find applications in various sectors including engineering, automotive, aerospace and general manufacturing, providing consistent surface finish and microfeed accuracy for both small and bulk volume works.

Certifications, Packaging, and Export Market Availability

Our grinders come with industry-leading certifications that assure product quality and operational safety. All stock is ready for quick dispatch with carefully packaged and securely shipped goods. Packaging details ensure damage-free delivery worldwide. Main export markets include Europe, Middle East, Africa, and Asia. Rate advantages paired with reliable delivery schedules make these machines favored by distributors, exporters, and wholesalers across the globe.

FAQs of Automatic Surface Grinders:

Q: How does the Automatic Surface Grinder achieve such a high surface finish quality?

A: The machine uses precise microfeed controls with a least count of 0.001 mm and high-performance grinding wheels, ensuring consistent surface finish quality up to 2 microns across various metal surfaces.Q: What is the range of table sizes and grinding wheel sizes available for this grinder?

A: Table sizes range from 300 x 600 mm to 500 x 1000 mm, while grinding wheels vary from 200 x 13 x 32 mm up to 350 x 35 x 127 mm, letting you select the right model for different workload requirements.Q: When can I expect my order to be shipped after purchase?

A: Stock is ready, and goods are shipped promptly after order confirmation, with packaging designed to ensure safe and secure transport to your location.Q: Where are these Automatic Surface Grinders commonly applied?

A: They are widely used in workshops, tool rooms, manufacturing units, and for specialized applications within die making and mold industries, offering versatile grinding solutions for metal surfaces.Q: What accessories are included with the surface grinder?

A: Each unit comes equipped with a magnetic chuck, coolant pump, wheel balancing stand, diamond dresser, and panel-based controls to support seamless operation and optimal grinding results.Q: How does the machine provide efficient and consistent grinding performance?

A: Featuring variable speed, hydraulic/servo force, and robust construction, the machine ensures stable, high-efficiency grinding operations suitable for both high-precision work and larger volume demands.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hydraulic Surface Grinders Category

Surface Grinder Machine

Price 540000 INR / Piece

Minimum Order Quantity : 1 Piece

Body Material : Other, Cast Iron

Power Source : Electric

Size : Standard

Product Type : Surface Grinder Machine

Hydraulic Surface Grinding Machine

Price 7000000 INR / Piece

Minimum Order Quantity : 1 Piece

Body Material : Other, Cast Iron

Power Source : Electric

Hydraulic Surface Grinder

Price 700000 INR / Piece

Minimum Order Quantity : 1 Piece

Body Material : Other, Cast Iron

Horizontal Surface Grinder

Price 165000 INR / Piece

Minimum Order Quantity : 1 Piece

Body Material : Steel

Power Source : Electric

Size : Standard

Product Type : Horizontal Surface Grinder

|

GURU AMAR DASS MACHINE TOOLS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry